Hemming Systems

Hemming is a technology used by the automotive industry to join inner and outer closure panels together (hoods, doors, tailgates, etc.). It is the process of bending/folding the flange of the outer panel over the inner one. The accuracy of the operation affects significantly the appearance of the car’s outer surfaces and is therefore a critical factor in the final quality of a finished vehicle.

Hemming is performed in order to:

- Achieve a better final geometry in the vehicle´s part

- Add resistance and rigidity to the part

- Allow a safe handling of the part

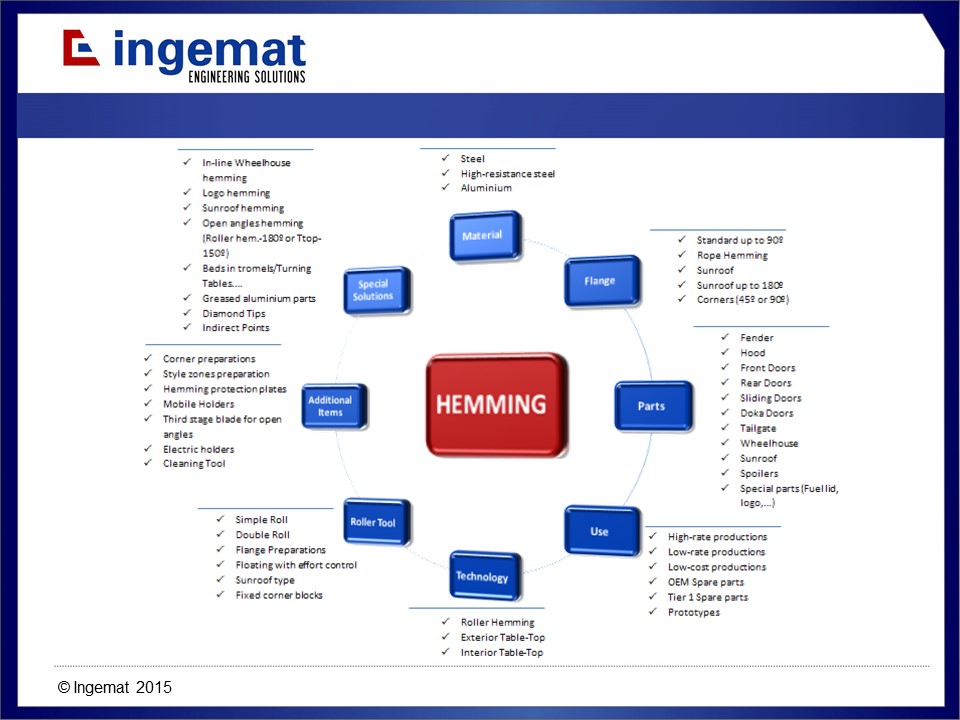

Hemming process can be carried out in diverse vehicle components: closures (Hood, doors, tailgates), sun roof, fenders, wheelhouses and in special applications such as fuel lid, brand and special parts. Both the outer perimeter and the inner frame of the part can be hemmed.

INGEMAT offers both the TABLE-TOP hemming technology as well as the ROLLER hemming technology, which can be performed both in Steel and aluminum parts. The reason to choose one technology (table-top / roller hemming) is mainly based on the cycle time of the vehicle to be produced.

In order to achieve the final quality, INGEMAT relies on a detailed analysis, at the beginning of the project, of the behavior of the metal sheet and its characteristics. One of INGEMAT’s differential elements is the vast experience in the relationship with the die-maker, which allows us to reach, after a cooperation process, the optimal product quality, ensuring the key success factors of the project.

Thanks to its deep know-how and its enormous experience in the hemming process, INGEMAT has become an international benchmark within the automotive sector in this field of technology.

The main characteristics of the two hemming systems offered by INGEMAT are: